The Challenge:

The Challenge:

DMC Power's engineering team faced a dual challenge presented by a major Northeast United States Utility. The need was to address two common issues encountered on job sites:

- Heavy Cable Handling: Addressing the cumbersome task of lifting and installing heavy lengths of cable.

- Replacement of Failed Cast Connectors: Swiftly replacing cast connectors responsible for outages across various job sites.

The aim was clear: to provide a simple, efficient, and implementable solution that would effectively resolve both challenges for the customer. DMC Power took on the task of custom-engineering specialized solutions to enhance the efficiency and reliability of split pad installations, ensuring consistent and reliable grounding systems that could sustain diverse environmental conditions. Upon diligent research and comprehensive analysis, our engineering group delved into design modifications and rigorous lab testing.

The Solution:

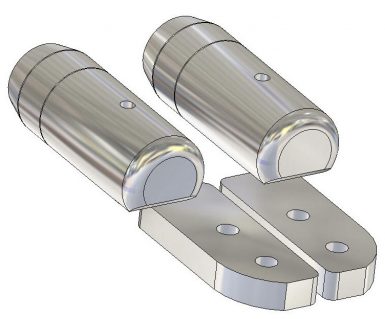

The ingenuity lay in transforming the traditional 4-hole pad into two separate Right and Left modified 2-hole pads. By halving the weight of the permanent cable attachments, this innovation significantly eased the process of lifting and installing even the largest and heaviest cables, making the operation far more manageable.

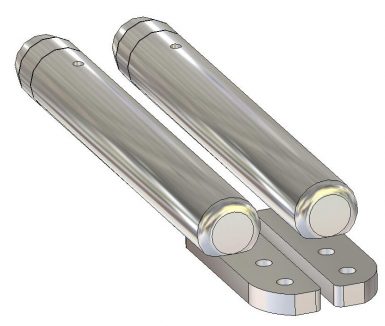

Furthermore, the introduction of adjustable barrel lengths in the design allowed for a fully customizable configuration. The ability to adjust barrel distances ensured not only optimal spacing but also facilitated swift and seamless installation, an aspect crucial during urgent repairs.

By acknowledging the shortcomings of the old cast connectors - prone to splitting due to inferior materials and ice accumulation issues stemming from the absence of a weep hole - our solution involved designing long barrel versions. This modification enabled the preservation of existing cable runs, swift replacement during outages, and considerable time and cost savings for the customer.

Moreover, these long barrel connectors demonstrated versatility by serving as standoffs on substation switches, expanding their utility beyond the initial application.

All connectors underwent rigorous design and testing processes, ensuring a welded strength rating 50% higher than the Utility's considerations for worst-case scenario breakage due to environmental factors like wind, ice loads, and major faults.

The Results

Through innovation and meticulous engineering, DMC Power not only met but exceeded expectations. The swift resolution of the challenges within a tight timeframe showcased the adaptability and efficiency of our solutions. The successful project completion, marked by enhanced efficiency and cost savings, left both the contractor and customer highly satisfied with our capabilities and commitment to excellence.

The customer's satisfaction was paramount. The contractor, tasked with replacing failed connectors across various substations within a stringent 24-day deadline, accomplished the entire project within a mere 8 days. This swift and incident-free completion demonstrated the efficiency and effectiveness of our solution. Our rapid development of a solution tailored precisely to their needs, integrating superior materials, lightweight tools, single swage installation, and leveraging our in-house design, testing, and manufacturing capabilities, left them extremely pleased.

Have a challenge in need of custom solutions? Contact a DMC Power Territory Manager today!

(Click to enlarge gallery images)