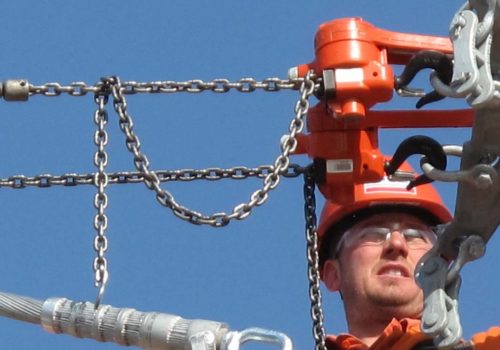

Pre-installed 4130 Chromaly Eyeloop in vertical and horizontal configurations

6061 aluminum barrel is preloaded with AFC compound for corrosion and oxidant protecton

Internal step down provides cable "choking" point and adds stress relief for maximum grip

Fewer Swages

0°, 15°, 45° and custom angles for single and dual pad Deadend to Jumper Terminal

Making Transmission connections on All Aluminum Core (AAC) conductor types just got a whole lot easier with DMC Power's AAC Connectors By adopting the design and technology principals used in our substation Cable connectors, DMC Power can quickly and easily hang your AAC cable in a matter of minutes with our simple 4-step process:

1. TRIM the conductor and brush the end to remove any cable rust and oxidation

2. INSERT the cable directly into the connector

3. SWAGE the connector in between the designated Swage lines

4. INSPECT the connector with our simple Go/No-Go Gauge to ensure the connector is fully compressed around the cable

AAC Connector Features

- Designed with major internal step down for stress relieve and "choking" effect for maximum cable grip

- Less compressions than competitor connectors

- 4130 Chromoly Steel Eye Loop - higher quality steel, higher strength rating, galvanized for corrosion resistance, vertical or horizontal orientations available

- Barrel interior comes loaded with AFC compound for corrosion and oxidation resistance

- EHV rated versions available

- Tested to Class A Rating

- Minimum 95% of RBS (most were 100-110%)

- Ran 40° cooler on 500 & 1,000 cycle Heat Rise tests with tenths of a micro OHM change in resistance

- 500 hours of Salt Spray Testing with no abnormal destruction or change in resistance

- 20 Freeze-Thaw cycles with no noticeable change in resistance