Due to its excellent conductivity, low weight and high overall tensile strength, Aluminum-Conductor Steel-Reinforced (ACSR) cables are some of the most popular in the industry.

Single Stage Installation

Our single stage connector system is the only class "AA" rated system for ACSR conductors and are tested to meet all requirements of ANSI C119.4, which requires 175°C rise over ambient temperatures. In fact, our connectors performed so well with near perfect stability in both temperature and resistance testing that we subjected the samples to an additional 500 cycles and still met the requirements of less than 5% change in resistance and a temperature range within the factor of 10.

Collet Design

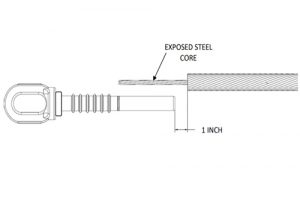

Did you know that factory applied internal grit to the steel holding member contributes up to 40% of holding strength? Installers regularly encounter cables like the one shown here and have no other option but to hammer it into fixed extrusion tubes and more often than not scrape out the internal grit.

But not with DMC Power's unique quad-collet design. Installers are able to open the collet as wide as necessary to secure the flared out cable without losing grip and increasing the contact area, resulting in core member holding strength that is far superior to tri-lope designs. Additionally, the installation orientation of our collet is universal whereas other tri-lope collets can lose up to 12% holding strength just depending on their installation orientation - are you confident your crews know the exact placement needed?

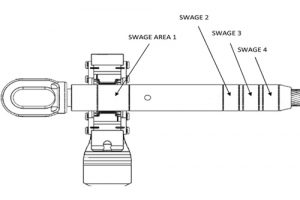

2-Stage Installation

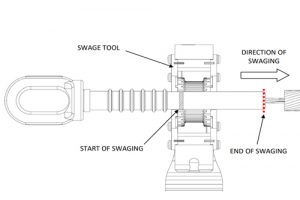

The installation process for 2-Stage ACSR connectors is quick and easy. All you need is one DLT85 Power Unit and two interchangeable sets of 360° flex dies, one for the inner gripping core and the other for current carrying aluminum outer barrel.

The internal core eye loop and/or internal splice sleeve are both made of high strength steel, machined to a precise tolerance of +/- .005" and come pre-coated with high grip material on the inside, resulting in the highest shear resistance capacity.

The outer aluminum barrels are designed with the same high conductivity 6000 series aluminum alloy used in our single stage system. This alloy has an IACS rating of 57% - a 40% increase over legacy fixed die systems!

These connectors are available in all application functions or specially designed to meet any project need.