Superior Design

Matching the proven CTC housing and collet system

for mechanical holding strength and the DMC Power

Swage System for electrical performance provides the

most technologically advanced connector system for

ACCC.

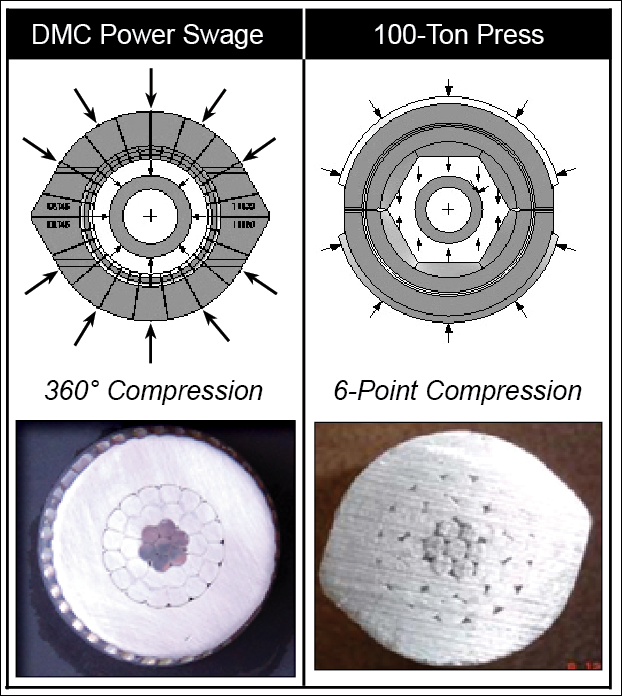

DMC Power’s Swage System offers more than twice the

compression area than traditional 100-ton presses! This

is a result of our unique 360° flex die technology which

distributes forces evenly around the entire diameter of the

connector barrel.

GREATER COMPRESSION =

- MORE ELECTRICAL CONTACT SPOTS

- LOWER RESISTANCE

- LOWER TEMPERATURES

Top Quality Materials

Unlike other global suppliers that use 6000 series alloy for ACCC fittings, DMC Power has chosen the purest aluminum alloy available in a compressible form 1100-H12.

| DMC Power | Competitor | |

|---|---|---|

| Aluminum Alloy | 1100 | 6000 |

| Conductivity (IACS %) | 57% | 40% |

| Manufacture Method | Machine Drilled | Drawn |

Fastest, Safest Installation Method

Give the efficient method the 360° flex Swage die applies forces to the

connector barrel we do not need a 100-pound (45Kilo) press head! All

DMC connector for ACCC size Lapwing and below can be installed

with our 45-ton tool weighing just 27 pounds (12Kilo). Shown below

in operation, this tool is safe and easy to use and requires only two

different dies which cover the complete line of ACCC CTC conductors.

Tested and Certified

Runs Cooler, Longer

Both DMC barrel diameters, 2.00” with Grosbeak and 2.50” with Lapwing were tested to IEC 61284 and met the acceptance criterion for both mechanical and current cycle test. These two barrel diameters cover all ACCC sizes up to and including Lapwing.

During ANSI C119.4 type testing, DMC Power ACSS Deadends and Splices showed superior resistance stability on all samples through 500 thermal cycles at 250°C-285°C above room temperature. Additional extreme temperature cycling to 325°C was performed for 280 more cycles with all samples averaging 50% cooler than the control and the post-aging tensile load yielding 104% RBS.

Thermal Mechanical Testing

Our ACSS line of high temperature Dead-ends and Splices have been independently tested to the rigorous international standards of CIGRE TB 426. Accordingly, samples were subjected to 500 current cycles at

250°C with 25% RBS constant tension including 5 separate sustained holds at 70% RBS for 24 hours. All DMC Power connectors passed easily with the post-aging tensioned conductor breaking at a remarkable 103% RBS.

As a result of these tests DMC Power has received CTC Global qualification for full tension transmission applications!

Based on the results of these tests CTC Global has qualified DMC as a supplier of partial tension fittings for substation applications where ACCC is fast becoming the conductor of choice for high operating temperature strain bus application.