The Problem:

In response to a specific request from a client in the Pacific Northwest, DMC Power undertook the manufacturing of specialized flexible, flat copper Bus connectors for a crucial substation repair project.

The use of copper bus in older substations and industrial facilities, owing to its high current carrying capacity, often presents challenges during retrofits and upgrades. In this instance, the introduction of new equipment with different dimensions necessitated innovative solutions to accommodate the offset.

- Legacy Copper Bus Challenges: Older substations, originally designed when copper prices were lower, posed challenges in accommodating modern equipment.

- Dimensional Misalignment: The new equipment's distinct dimensions did not align with the existing infrastructure, requiring flexible solutions for seamless integration.

The Solution:

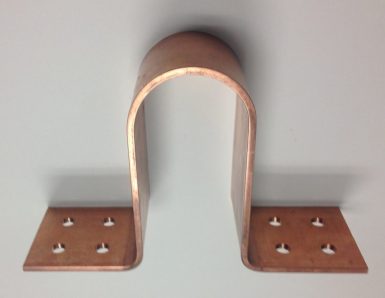

Drawing on DMC Power's expertise in Swage-able copper Bus and Cable connectors, this unique opportunity allowed the development of tailored solutions for flat Bus connectors.

- Consultation and Collaboration: Working closely with the customer, approved drawings for flexible copper bent flat Bus connectors were swiftly developed.

- Downloadable Resources: Providing convenient access to the approved drawings for seamless collaboration and implementation.

Upon receiving the Purchase Order (PO), the manufacturing process commenced:

- High-Quality Copper Sourcing: Utilizing top-notch copper sheet stock to ensure durability and reliability.

- Precision Bending and Shaping: Crafting connectors with meticulous precision to meet the unique dimensional requirements.

- NEMA Hole Patterns Addition: Enhancing versatility by incorporating NEMA hole patterns for easy mounting on the customer's transformers and switches.

The Results:

The tailored solution had a significant impact on the substation repair project:

- Seamless Integration: The flexible copper bent flat Bus connectors seamlessly accommodated the dimensional offset, ensuring compatibility between new and existing equipment.

- Versatility and Adaptability: The addition of NEMA hole patterns enhanced the connectors' versatility, facilitating easy mounting on various equipment.

DMC Power's ability to swiftly understand, collaborate, and deliver tailored solutions underscores its commitment to innovation. This case exemplifies our dedication to providing specialized solutions, even in scenarios where traditional products may not suffice.

Have a challenge in need of custom solutions? Contact a DMC Power Territory Manager today!