The Challenge: Weather-Induced Bus System Vulnerabilities

A municipal transit authority faced recurrent challenges during freeze-thaw cycles, witnessing bus system vulnerabilities that led to operational disruptions. While checking the Foster Substation, located near Hermiston, Oregon, the Umatilla Electric Cooperative (UEC) discovered seven vertical locations on the 1½” Bus had cracked due to freeze/thaw effects.

Welding vertical Bus connections in rain and mild wind conditions would have been especially difficult and required the services of an outside contractor. With 10 days to repair these connections, UEC turned to DMC Power to deliver:

Welding vertical Bus connections in rain and mild wind conditions would have been especially difficult and required the services of an outside contractor. With 10 days to repair these connections, UEC turned to DMC Power to deliver:

• (7) 1½” Bus Splices - PLK1000D24A

• (7) 1½” Offset Bus Terminals - PLK1880D24A

• 1½" Swage Tooling (DLT58MAPW000)

The Execution: Tailored Weather-Resistant Solutions

- Detailed Solution Approach: DMC Power undertook an in-depth analysis of the bus system and weather-induced vulnerabilities.

- Focused Design and Engineering: To prevent future freeze-thaw occurrences, the DMC Power engineering department modified the existing Offset Bus Terminals to include a weep hole.

- Timely Execution: Meeting their 10-day timeframe, DMC Power representatives arrived on site with the connectors and Swage tooling required.

- Fast, On-Site Training: The construction crew was brand new to Swaging and allotted three days of total outage time after delivery of the connectors. Within 30 minutes, DMC Power's Territory Manager had the crew fully trained and ready to Swage.

The Results

The implementation of DMC Power's weather-resistant solutions resulted in tangible improvements and cost-savings for the client.

- Efficient Installation: UEC was able to use their own crews instead of a specialized welder, saving two full outage days and the cost of the outside contractor.

- Reduced Downtime: In additional to a substantial decrease in system downtime during freeze-thaw cycles, all connectors were installed, inspected and the substation was back in service before lunch on the day of delivery.

- Improved Durability: Enhanced resilience, minimizing connector failures and maintenance needs.

- Operational Consistency: Improved bus system reliability and operational consistency.

“DMC Power was able to ship us the connectors in less than 10 days and provided onsite training. The installation was extremely fast, and we were able to re-energize the substation the same day.” Umatilla Electric Co-Operative Crew Member

Have a challenge in need of custom solutions? Contact a DMC Power Territory Manager today!

(Click to enlarge gallery images)

- Foster Substation

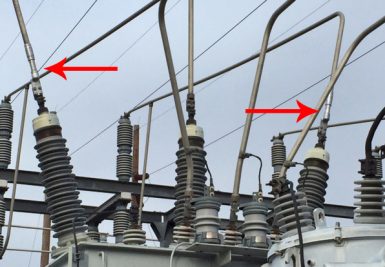

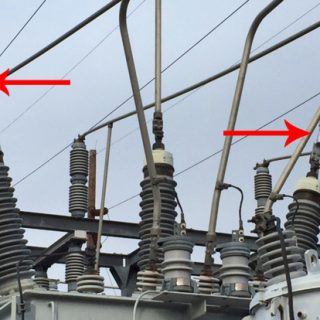

- Freeze/Thaw Damage

- Damaged Bus

- Damaged Bus

- Damaged Bus

- Installing DMC Power Connectors

- Installed DMC Splice

- Replacement Splice & Terminal

- Replacement Splice & Terminal

- Replacement Splices & Terminals

- Swage Tool Training Setup