Why is copper used as a conductor?

Behind only silver, copper is the most common conductive metal with an IACS rating of 100%. Nearly every product that requires high conductivity, including electronic products, automobiles and power distribution/generation, use copper conductors.

Copper also has fantastic tensile-strength, thermal-conductivity and thermal-expansion properties. The flexibility of copper wiring makes it easy to install yet remain strong enough to allow the conductor to remain solidly secured.

Lastly, copper has excellent environmental exposure properties, particularly in damp coastal and other high corrosive environments. Rusting is an issue for all metals but when copper rusts the oxidized metal is still conductive.

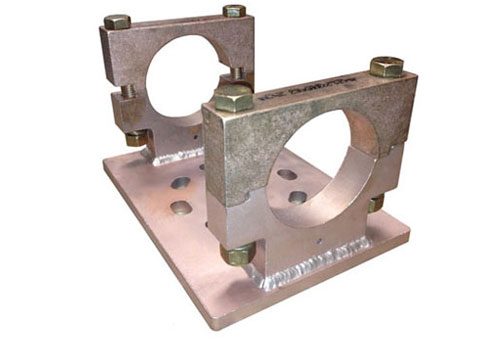

Why DMC Power Copper Bus Connectors?

Because we know connectors better than anyone.

- All connectors are designed and engineered in-house to the exact same specifications and standards that meet or exceed our Aluminum Bus Connectors.

- We use 100% pure virgin copper that is free of impurities. This allows complete and total conductivity between your conductors and our connectors.

- Because of the relationships we have with our copper mill, the raw material for your project typically arrives within 24 hours of the purchase order being received. This saves 1-2 weeks right at the start of the project versus competitors.

- No part of the manufacturing process is outsourced. Once the material is received and inspected for quality it goes straight into machining at our ISO certified facility, saving even more time on your order.

- DMC Power uses an experienced crew of TIG welders who specialize in the precise welds copper requires.

- For the transition from copper to aluminum so offer tin plate on all connectors as well as bi-metallic transition plates.

Ordering Information

A small sample of our Copper Bus Connectors are available to view online, but ANY Aluminum Connector can easily be made into a copper equivalent using the same NPS sizes and Swage Tooling.

| Material | Aluminum | Copper | |

| Style Prefix | PLK | CPL | Changes based on material |

| Material Code | D | B | |

| NPS Code | ## | See NPS Size Chart | |

| Secondary | ## | Optional - second bus, angle, bolt circle, NEMA Pad size | |

| Tin Plated? | # | Optional - No=Blank, Yes=T | |

| Complete Part Number |

(click to view) |

(click to view) |

|

| Verbal Description | 1" Aluminum Bus Splice | 1" to 1" Copper Bus Tee, 0°, Tin Plated | |

For information on parts not listed online, Copper Tubing, custom designs, questions or more information, contact DMC Power directly.