In September 2015, DMC Power initiated a thermal mechanical research project with Kinectrics to evaluate the performance of Single Stage ACSR Swage connectors under tension and high temperature operation.

In September 2015, DMC Power initiated a thermal mechanical research project with Kinectrics to evaluate the performance of Single Stage ACSR Swage connectors under tension and high temperature operation.

The three primary objectives of this study were to (1) study the effects of tension on thermal cycling on a Single Stage Swage technology connector system; (2) study the effects of inhibitor compound in both temperature and resistance, including post aging mechanical performance and; (3) compare results to previous test performed on conventional Single Stage Connector (SSC) systems.

White Paper | Thermal Mechanical Presentation

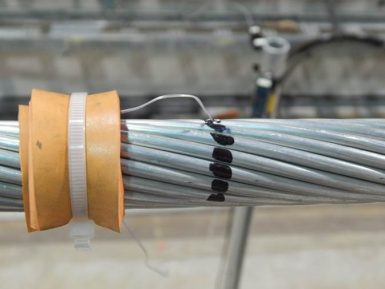

TEST SETUP

- Two 795 ACSR lines -- (2) Dead Ends & (2) Splice each on the line.

- Line sample #1 included oxide inhibitor compound prior to installation.

- Line sample #2 installed per standard Swage SOP - NO compound applied prior to Swaging.

- Following a previously established protocol, Swage Type Connectors were tested in an accelerated aging process.

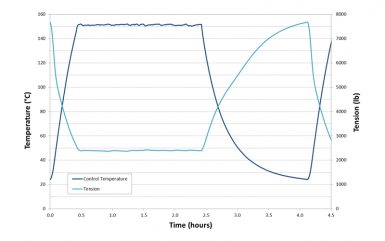

- Steady temperature = 150⁰C

- Total number of current cycles = 1,100

- Current on-time = 2 Hours

(Click to enlarge)

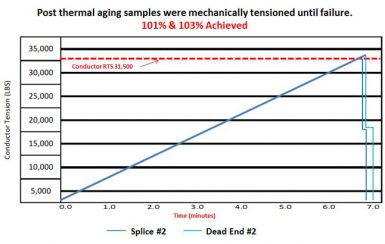

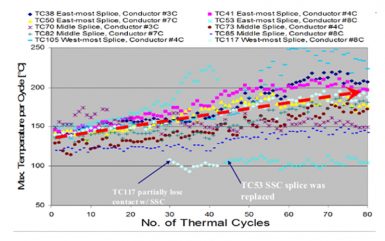

TEST RESULTS

Data Charts

(Click to enlarge)|

|

|

||

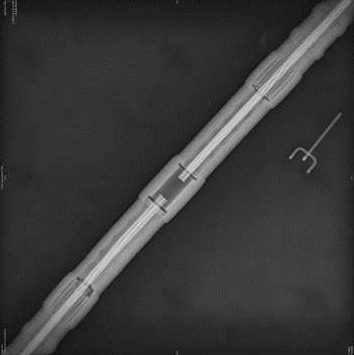

Digital Radiography Imaging

- Images taken before and after thermal cycling confirm no movement of the steel core was exhibited throughout the test.

ACSR Thermal Mechanical Testing confirms the DMC Power Swage System is superior to other systems and that Swage samples without inhibitor exhibited higher performance.

In previous test conducted by EPRI under the same protocol on conventional SSC systems, all samples failed by temperature differential within the fit 100 cycles.

Traditional ANSI type test current is passed through connector samples while

Traditional ANSI type test current is passed through connector samples while